RF Welding vs Ultrasonic Welding: A Comparison

When it comes to joining components together, there are two primary methods of welding that are widely used - Radio Frequency Welding (RF) and Ultrasonic Welding (USW). Each has its own distinct advantages and disadvantages, making them ideal for different applications. So how do you choose between RF and USW? Let's take a closer look at each to see how they compare.

What is Radio Frequency welding?

Radio Frequency welding is a type of non-contact joining process that uses an alternating current to generate heat. It is also known as High Frequency Welding and is commonly used in the production of items such as airbags and seat belts.RF welding uses a combination of heat and pressure to fuse two or more materials together. It is often used on thermoplastics and films but can also be employed to weld metals such as aluminum and nickel when used in conjunction with a conductive foil.

What is Ultrasonic Welding?

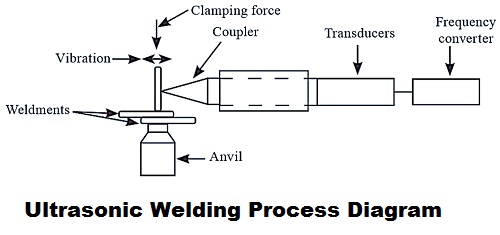

Ultrasonic welding is another type of non-contact process that combines heat and pressure to create a permanent joint. The major components of ultrasonic welding are frequency converter and a transducer. It utilizes high frequency sound waves to generate localized heat at the joint, which results in a very strong, reliable bond. USW is often used for joining plastic components together, but can also be used for some metals as well.

Advantages of RF Welding

The primary advantage of RF welding is its speed. It is one of the fastest non-contact joining processes and is capable of welding components together in just a few seconds. It is also an extremely efficient process, as it requires minimal energy to achieve satisfactory results. RF welding is also relatively easy to set up and operate, and is highly accurate.Advantages of Ultrasonic Welding

The primary advantage of Ultrasonic Welding is its precision and repeatability. It produces very consistent and reliable results, making it ideal for precision applications. USW can be used in a wide range of materials, including thermoplastics, metals, elastomers, and composites. It is a relatively fast process, but not as fast as RF welding.Disadvantages of RF Welding

The primary disadvantage of RF welding is its limited versatility. It is typically only used for welding thermoplastics and films, and is not suitable for other materials. It is also not as precise as USW, which limits its utility in certain applications. In addition, RF welding can produce a very loud noise, making it unsuitable for certain environments.Disadvantages of Ultrasonic Welding

The primary disadvantage of USW is its complexity. It requires careful and precise setup and requires monitoring throughout the process.It is also slower than RF welding and requires more energy to achieve satisfactory results. In addition, USW is not suitable for all applications, such as joining soft materials or very thin components.

Conclusion

Both RF and USW have their own distinct advantages and disadvantages, which makes them ideal for different applications and materials. RF welding is a very fast and efficient process that is often used for welding thermoplastics and films.On the other hand, Ultrasonic welding is a more precise process that is often used for joining a variety of materials, but it requires careful and precise setup and is slower than RF welding. Ultimately, the right choice will depend on the application and materials.

Comments

Post a Comment