Oxy acetylene vs arc welding

Both oxy-acetylene welding vs arc welding have their own unique advantages and disadvantages, so the choice between them will depend on the specific application and the skill level of the welder.

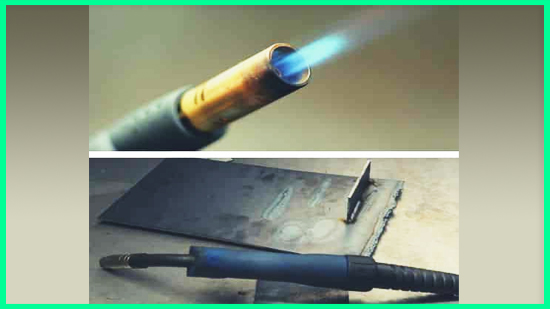

Oxy-acetylene welding, also known as gas welding, is a type of flame welding that uses a mixture of oxygen and acetylene gas to create a high-temperature flame. This type of welding is useful for welding a variety of metals, including steel, brass, and copper. It is also useful for brazing and soldering. However, it is not as strong as arc welding and it is considered to be less precise.

Arc welding, on the other hand, uses an electric current to create an arc between an electrode (the welding rod) and the metal being welded. This type of welding is much stronger than gas welding and is more precise. It is also more versatile, as it can be used to weld a wide variety of metals, including steel, aluminum, and cast iron. However, it does require more skill and experience to use than gas welding.

Welding is an essential skill in many industries, and it's important to understand the differences between the various welding techniques.

One of the most common welding techniques is oxy acetylene welding, which uses a combination of oxygen and acetylene gases to create a flame that melts metal.

Another popular technique is arc welding, which uses an electric current to create an arc that melts metal.

So which one is better for your project?

Well, it really depends on the type of material you're working with and the size of the project.

Oxy acetylene welding is generally better for smaller projects, as it's easier to control and requires less setup time.

Arc welding is better for larger projects, as it's more efficient and can be used on thicker materials.

Ultimately, it's up to you to decide which welding technique is best for your project. But by understanding the differences between oxy acetylene and arc welding, you can make an informed decision and get the job done right.

Oxy acetylene vs arc welding: What's the difference?

Oxy acetylene and arc welding are two of the most popular welding techniques used in metalworking. But what are the differences between them?

Oxy acetylene welding is a type of gas welding that uses a combination of oxygen and acetylene gases to create a flame that is hot enough to melt metal. This type of welding is great for welding thin pieces of metal together, as well as for brazing and soldering.

Arc welding, on the other hand, is a type of welding that uses electricity to generate heat. It is used to weld thicker pieces of metal together, as well as to create strong welds in hard-to-reach places.

The main difference between oxy acetylene and arc welding is the heat source. Oxy acetylene welding uses a flame to generate heat, while arc welding uses electricity.

The other main difference is the type of metal that can be welded. Oxy acetylene welding works best with thin pieces of metal, while arc welding is better for thicker pieces.

When it comes to safety, both types of welding can be dangerous if not done correctly. Oxy acetylene welding creates a lot of heat and can cause burns if not handled properly, while arc welding can cause electric shocks if not done correctly.

Both types of welding have their advantages and disadvantages. Oxy acetylene welding is great for thin pieces of metal and can be used in tight spaces, while arc welding is better for thicker pieces of metal and can be used in areas with poor ventilation. Ultimately, it comes down to the type of project you're working on and which type of welding is best suited for it.

The Advantages of Oxy Acetylene Welding

Oxy acetylene welding is a popular welding technique that is used in many industries. It’s a reliable and cost-effective solution for joining two pieces of metal together.

The main advantage of oxy acetylene welding is that it’s a versatile process. It can be used to weld a variety of metals, including aluminum, stainless steel, and cast iron. It can also be used with different thicknesses of metal, making it a great choice for many welding projects.

Another advantage of oxy acetylene welding is that it’s a relatively fast process. This makes it ideal for large-scale projects where speed is of the essence. It’s also more efficient than other welding techniques, which can save time and money.

The process itself is also relatively simple and easy to learn, making it a great choice for beginners. It requires minimal equipment and can be done relatively quickly.

Finally, oxy acetylene welding is a safe process. It doesn’t require the use of any flammable liquids or gases, which makes it a safer option than other welding techniques.

Overall, oxy acetylene welding is an effective and reliable welding technique that offers many advantages. It’s versatile, fast, efficient, and safe, making it an excellent choice for many projects. Whether you’re a beginner or an experienced welder, oxy acetylene welding is worth considering.

The Disadvantages of Oxy Acetylene Welding

Oxy acetylene welding is a popular welding process that is used in many industries. It is a reliable and cost-effective way to join two pieces of metal together. However, there are some disadvantages to this welding process that should be considered before deciding to use it.

The first disadvantage of oxy acetylene welding is the risk of fire and explosions. This welding process uses a combination of oxygen and acetylene, which are both highly flammable gases. If the welding process is not done correctly, there is a risk of a fire or explosion occurring.

Another disadvantage of oxy acetylene welding is the cost. The equipment needed for this welding process is more expensive than other types of welding processes, such as stick welding. Additionally, the gases needed for this process are also more expensive than other types of welding gases.

The third disadvantage of oxy acetylene welding is the amount of time it takes to complete a weld. This welding process is slower than other types of welding processes, such as MIG or TIG welding. This means that it will take longer to complete a project using this welding process.

Finally, oxy acetylene welding produces more smoke and fumes than other types of welding processes. This can be a health hazard for those who are exposed to the smoke and fumes produced during the welding process.

Overall, oxy acetylene welding is a reliable and cost-effective way to join two pieces of metal together. However, there are some disadvantages to this welding process that should be considered before deciding to use it. These include the risk of fire and explosions, the cost of the equipment and gases, the amount of time it takes to complete a weld, and the amount of smoke and fumes produced.

Differences Between Oxy Acetylene and Arc Welding

Oxy acetylene and arc welding are two popular welding techniques used in many industries. Both techniques can be used to join metal parts together and create strong, durable welds. However, there are some key differences between the two that should be taken into consideration when deciding which welding technique is best for a given project.

Oxy acetylene welding uses a combination of oxygen and acetylene gases to create a high-temperature flame. This flame is then used to heat the metal parts to be joined and create a weld. This technique is best used for thin sheets of metal, as it provides a precise and controlled heat source.

Arc welding, on the other hand, uses an electric current to heat the metal parts. The electric current is created by a welding machine and flows through a welding rod, which is held between the two metal parts. The heat created by the electric current melts the metal parts together, forming a strong weld. Arc welding is best used for thicker pieces of metal, as the heat source is more powerful than that of oxy acetylene welding.

Both oxy acetylene and arc welding can be used to create strong and durable welds. However, there are some key differences between the two that should be taken into consideration when deciding which technique to use. Oxy acetylene welding is best for thin sheets of metal, while arc welding is best for thicker pieces of metal. It is important to understand the differences between the two techniques in order to choose the right one for a given project.

Which is Right for You Oxy acetylene vs arc welding?

Oxy acetylene welding is a less expensive option that is often used for welding thin metal sheets together.

Arc welding is more expensive, but it is better suited for welding thicker metal plates together.

The main difference between oxy acetylene and arc welding is that oxy acetylene welding is less powerful and is often used for welding thin metal sheets together.

Arc welding is better suited for welding thicker metal plates together because it has a greater welding power and is less likely to cause damage to the metal.

If you're looking to weld thicker metal plates together, arc welding is the method for you.

However, if you're only welding thin metal sheets together, oxy acetylene welding is a good option.

The main advantage of arc welding is that it has a greater welding power and is less likely to cause damage to the metal.

If you're looking for a less expensive option, oxy acetylene welding is a good option.

However, if you're looking for a more powerful option, arc welding is the right choice for you.

Comments

Post a Comment